Northfield offers the highest level of support in every market we serve.

Your Full-Service Transformer Partner

End-to-End Support Services

-

Consultation

Whether you’re replacing one transformer or need dozens for a new data center location, we’ll work with you to provide transformer solutions tailored to your specialized needs, including design and design verification and oversight in sourcing key materials.

-

Production Management

We know every second counts, and we’ll keep you ahead of schedule in the manufacturing process. Our procurement, production, and logistics networks enable us to meet complex specifications and quality achievements with faster lead times than anyone else.

-

Inspection and Testing

You shouldn’t accept anything but the highest quality, and we won’t offer you anything short of it. Our British quality control engineers offer independent and factory acceptance testing (FAT) oversight, ensuring full operation and minimal downtime.

-

Transportation

Moving transformers to where you need them is cumbersome to do on your own. We’ll handle all the logistics, including DDP project location, customs clearance, and delivery from the production facility to your site.

-

Installation

Forget about improper installation or not having the right staff on hand. Our local operations and technical team will erect and install all equipment for you, so your transformers get up and running the right way, right away.

-

Maintenance

We stand by our products, and our relationship doesn’t end after installation. With local technical site acceptance testing (SAT) and warranty services, you’ll receive white glove support should any parts need repair or replacing.

With Our Global Footprint And Full Range of Installation, Testing, And Maintenance Capabilities

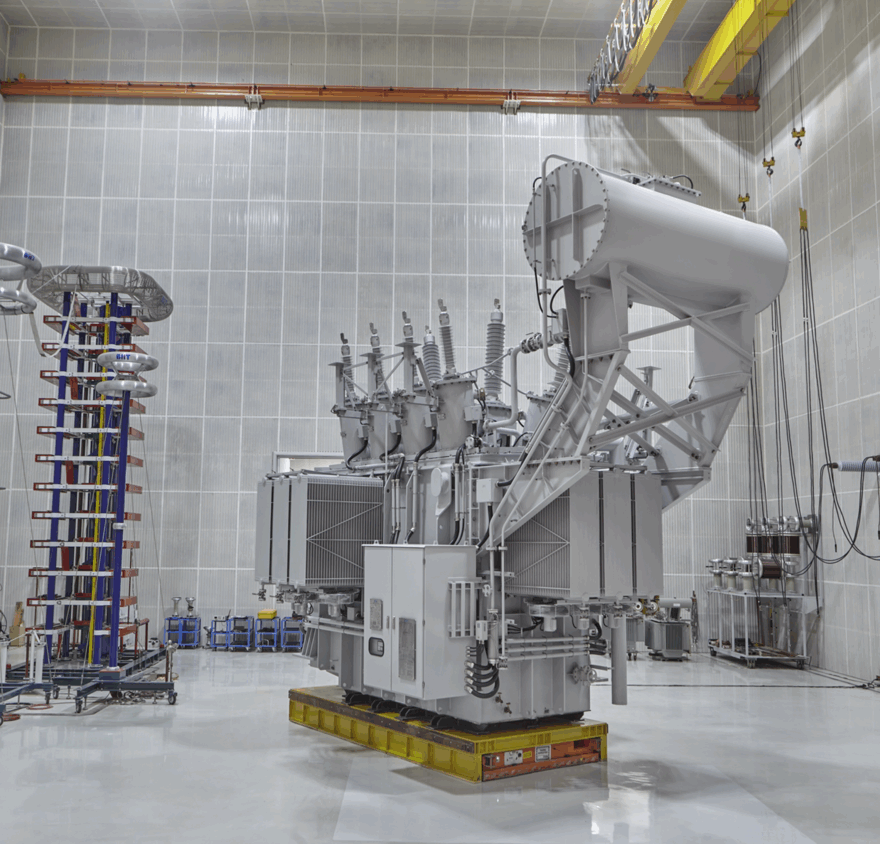

In-House Testing

Northfield transformers are designed, manufactured, and tested to the highest standards, ensuring reliable performance and longevity.

Our high level of quality control is maintained by British engineers who oversee the production process from start to finish, and accompany the equipment to your site for installation and commissioning. Each of our manufacturers has an in-house certified laboratory for FAT, including type and routine testing.

Hands-On Installation

No matter the environment, our transformers are built with both performance and longevity in mind.

Our logistics team engages with contacts at every touchpoint to ensure the integrity of your equipment. Your assigned team will manage transportation, including handling and customs clearance, to ensure safe delivery to the installation site.

Our local engineering team will help guide installation so your equipment is set up correctly, thoroughly tested, and ready for use.

-

Design and Engineering

Customized transformer designs to meet specific operational needs and compliance standards. -

Global Logistics Coordination

Seamless transportation, customs handling, and site delivery managed by our award-winning logistics division. -

Local Servicing

Local experts with the knowledge to maintain and optimize transformer performance.